Production & Supply

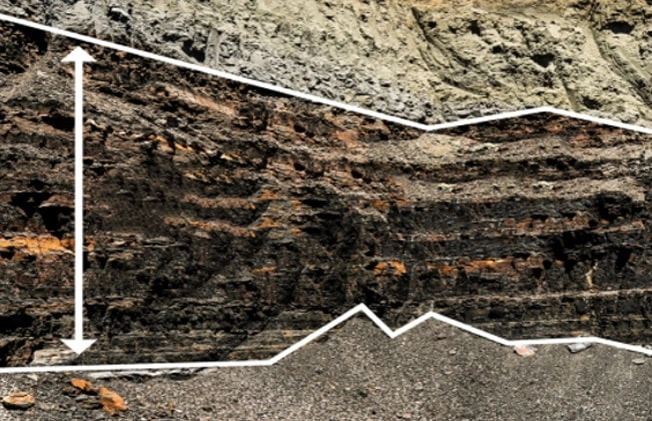

Raw Material Extraction

Localized procurement: Soybean meal, peanut meal

Global premium resources: Exclusive partnership with Nouryon

Centralized/mining-area strategic procurement: Lignite (with negotiated pricing)

-

01

Selecting High-Content & High-Activity Humic Acid Mineral Sources with Exclusive Distribution Rights

To screen the optimal raw materials

coal samples from 514 premium production areas were collected and tested.

-

02

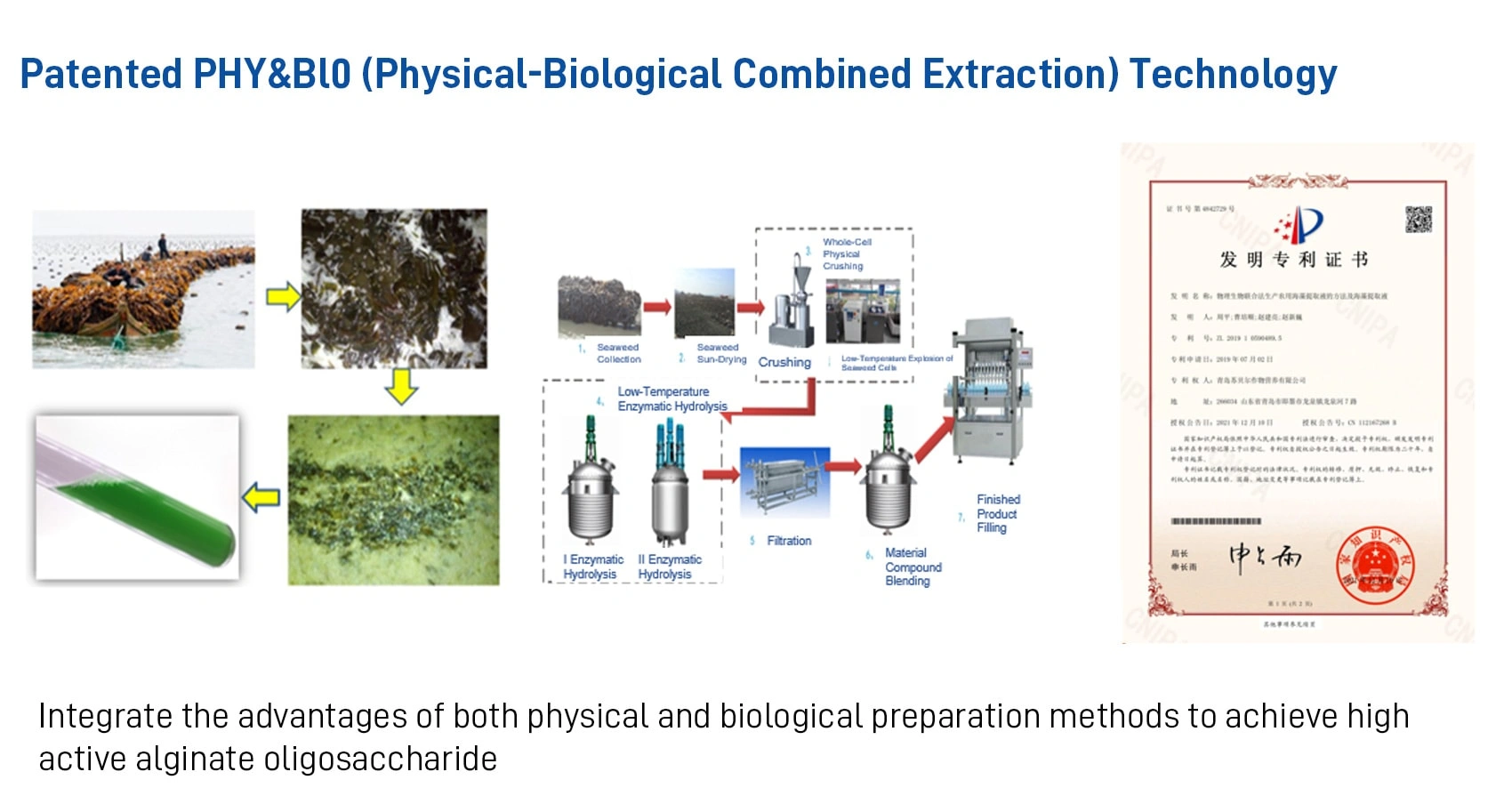

Alginate Oligosaccharide Derived from Globally Selected Brown Seaweeds

-

03

Amino Acid's Core Raw Material

Abundant Fishery Resources

Qingdao’s high-quality ports and marine fishery advantages have driven the development of a complete fish product processing industry, providing abundant fish-derived animal protein raw materials.

Strong Grain and Oil Industry

As a major population province and a key grain-producing area, Shandong has a robust grain and oil industry, which supplies abundant meal-based plant protein raw materials.