Bio-enzymatic hydrolysis technology is a process that uses enzymes as highly efficient biological catalysts to specifically decompose macromolecular substances into smaller molecules under mild conditions. Its core advantage lies in significantly reducing the activation energy required for the reaction, thereby achieving energy saving, safety, and environmental protection.

HSE

Reducing Chemical Fertilizer Usage, Improving Fertilizer Utilization Efficiency, Committed to Achieving Fertilizer and Pesticide Reduction Through Innovative Solutions, Making Agricultural Products Safer

We deeply recognize that the excessive use of traditional chemical fertilizers is not only a waste of resources but also poses serious challenges to soil, water bodies, and the atmospheric environment. Therefore, we place Reducing Fertilizer Input and Increasing Efficiency at the core of our HSE strategy. This is not simply about reducing input, but about systematically improving nutrient use efficiency through our innovative biostimulant products and solutions. Our products, such as biostimulants rich in specific humic acids, seaweed extracts, or amino acids, can achieve this goal through multiple pathways: activating fixed nutrients in the soil, converting them into forms available to crops; stimulating crop root development, expanding the nutrient absorption area; enhancing the crop's own physiological metabolism, improving the assimilation and transport of nutrients. This means that, under the premise of ensuring crop yield and quality, farmers can reduce chemical fertilizer input by 10%-30%. This directly reduces agriculture's dependence on chemicals, curbing non-point source pollution (such as water eutrophication) and greenhouse gas emissions caused by nutrient loss at the source. We are committed to helping Chinese agriculture achieve the Dual Reduction goals by providing environmentally friendly solutions, ultimately providing consumers with safer and healthier agricultural products, fulfilling our dual responsibilities for food safety and ecological protection.

Focusing on Soil Health, Resisting Salinity and Alkalinity

Soil is a precious non-renewable resource, and its health status is directly related to sustainable agricultural development. Our HSE philosophy extends to the proactive maintenance and restoration of the soil ecosystem. We pay special attention to soil degradation issues, especially salinization, which has become one of the main abiotic stresses constraining global agricultural production.

Our R&D direction and product design always consider soil improvement as a key factor. Our biostimulants can improve the physical structure of the soil through their specific functional groups, promote the formation of aggregate structures, break up compaction, thereby enhancing soil aeration, water retention, and fertilizer retention capacity. When facing salinity and alkalinity stress, our products can help crops maintain ion balance within the plant, reduce the absorption of harmful ions such as sodium ions, and enhance cellular osmotic adjustment capacity, ensuring normal crop growth under stress. Furthermore, the organic components in the products can serve as a carbon source for soil microorganisms, stimulating soil microbial activity, and gradually restoring a healthy soil micro-ecology. In this way, we are not just treating diseases but also nourishing the land, committed to reversing the trend of soil degradation, improving cultivated land quality, and leaving fertile, healthy farmland for future generations. This is our solemn HSE commitment to the land.

HSE Management System Benchmarks or Even Complies with the Global Standards of Leading Multinational Companies in the Industry

Benchmarking Against International Standards: Building a World-Class HSE Management System

We firmly believe that outstanding Health, Safety, and Environment (HSE) performance is the cornerstone for modern enterprises, especially those in the chemical industry, to achieve sustainable development. To this end, our HSE management system comprehensively benchmarks against, and even strives to surpass, the global standards of leading multinational companies in the industry, for example, following international best practices such as ISO 14001 Environmental Management System and ISO 45001 Occupational Health and Safety Management System. This is reflected in every aspect of our operations: on the production and manufacturing side, we adopt green and mild production processes (such as bio-enzymatic hydrolysis technology) to minimize energy consumption, reduce the discharge of three wastes, and ensure all emissions are strictly treated to meet or exceed national and local standards. Regarding employee safety and health, we have established a comprehensive hazard identification and risk assessment process, providing systematic HSE training for all employees (including R&D, production, and marketing staff), equipping them with personal protective equipment that meets international standards, and fostering a safety first corporate culture, pursuing the goal of zero accidents. In terms of full product lifecycle management, we evaluate the environmental and safety impacts from raw material selection, formula design, to packaging and transportation, ensuring our products are friendly and safe for people and the environment throughout the value chain. By building such a systematic, standardized, and transparent HSE management system, we aim to become a respected and responsible industry leader globally.

Bio-enzymatic Hydrolysis Technology Reduces Energy Consumption, Safer and More Environmentally Friendly

-

01

Energy Saving Advantages

Energy Saving Advantages

Mild Conditions and Efficient Catalysis

Compared with traditional methods, the energy-saving effects of enzymatic hydrolysis technology are mainly reflected in two aspects:

-

Mild reaction conditions, no high energy consumption required: Traditional methods rely on high-temperature cooking, high pressure, or strong acids and alkalis to destroy raw material structures, consuming enormous energy. In contrast, the enzymatic hydrolysis process can proceed at room temperature, atmospheric pressure, and suitable pH levels, eliminating the need for continuous energy input to maintain harsh reaction environments, fundamentally reducing thermal and electrical energy consumption.

-

High catalytic efficiency, shortened processing time: Enzymes have extremely high catalytic efficiency, enabling the decomposition of substrates in a short time, thereby significantly shortening the overall process cycle, reducing equipment running time, and indirectly achieving energy savings.

-

-

02

Safety Advantages

Safety Advantages

Comprehensive Risk Reduction

This technology enhances the safety of the production process and the final product from three dimensions:

-

Safer for operators: The enzymatic hydrolysis process avoids the use of highly corrosive chemicals and high-temperature, high-pressure environments typical of traditional methods, fundamentally eliminating occupational risks such as burns, scalds, and poisoning arising from them.

-

More friendly to production equipment: The mild reaction conditions reduce the stringent requirements on equipment materials, lessen corrosion on reaction kettles and pipelines, extend equipment lifespan, and lower the risk of leaks caused by equipment corrosion and perforation.

-

Ensures final product quality: The high specificity of enzymes ensures they only act on specific chemical bonds, avoiding the generation of harmful by-products, resulting in a high-purity final product with no safety hazards.

-

-

03

Environmental Advantages

Environmental Advantages

Green Manufacturing Across the Entire Chain

The environmental benefits of enzymatic hydrolysis technology run through the entire production chain:

-

Pollution reduction at the source: This technology avoids the use of strong acids, strong alkalis, and other inorganic chemicals, preventing the generation of high-salinity, difficult-to-treat wastewater at the source.

-

Low end-of-pipe treatment load: The wastewater generated by the enzymatic hydrolysis process mainly contains biodegradable organic compounds, making it easy to treat with conventional biochemical methods, reducing the difficulty and cost of wastewater treatment.

-

Contributes to carbon emission reduction: Due to the significant reduction in energy consumption, it indirectly reduces greenhouse gas emissions resulting from energy use.

-

Promotes circular economy: Enzymes themselves can be produced through microbial fermentation using renewable resources, reflecting the concept of resource recycling.

-

Bio-enzymatic hydrolysis technology fundamentally transforms industrial production from a high-energy-consumption, high-pollution forceful dismantling mode to a precise, mild, and efficient green manufacturing mode. It is not only one of the key technologies for current industrial transformation and upgrading and achieving the Dual Carbon goals but also an important foundation for building a sustainable bio-economy in the future.

Having a Scientific HSE Performance Management System. Briefly introduce how to achieve closed-loop management and continuous improvement of HSE goals by setting Key Performance Indicators (KPIs), regular evaluation and feedback, and digital tools.

-

Setting Key Performance Indicators (KPIs)

KPI setting must closely align with core HSE objectives, balancing comprehensiveness and operability, and be precisely decomposed across dimensions:

Health Dimension: Focus on ensuring employee occupational health, setting indicators such as Occupational Disease Incidence Rate (target 0), Occupational Health Check Coverage Rate (target 100%), Health and Safety Training Pass Rate(target ≥95%), etc., to ensure employees' health rights are practically guaranteed.

Safety Dimension: Focus on risk prevention and control and accident management. Core indicators include Number of Production Safety Accidents (target 0), Major Hidden Danger Rectification Completion Rate (target 100%), Safety Facility Integrity Rate (target ≥98%), Emergency Drill Pass Rate (target ≥95%), building a safety defense line through the entire process of prevention, rectification, and emergency response.

Environment Dimension: Centered on pollution control and green development, set indicators such as Pollutant Discharge Compliance Rate (target 100%), Waste Compliance Disposal Rate (target 100%), Energy Saving and Consumption Reduction Completion Rate (set specific values according to annual energy-saving targets), promoting the coordinated development of production and the environment.

Setting Principles: Follow the SMART principle (Specific, Measurable, Achievable, Relevant, Time-bound), adjusted differentially based on the company's industry characteristics, production scale, and risk level, ensuring the indicators are both challenging and aligned with actual operations.

-

Regular Evaluation and Feedback Mechanism

Establish a full-cycle evaluation and feedback system to ensure performance data is promptly converted into improvement momentum:

Evaluation Cycle: Implement a tiered evaluation mechanism of Daily Inspection + Monthly Assessment + Quarterly Review + Annual Evaluation. Daily inspections are recorded by on-site safety specialists for key indicator dynamics; monthly assessments consolidate data to form performance reports; quarterly reviews analyze reasons for indicator deviations; annual evaluations conduct comprehensive performance assessments based on yearly data.

Evaluation Methods: Adopt a combined model of Quantitative Data Statistics + Qualitative Comprehensive Evaluation. Quantitative data is automatically collected from production systems and monitoring equipment to ensure objectivity; qualitative evaluation is conducted by an assessment team combining employee safety behavior, emergency response performance, etc., for comprehensive scoring, compensating for the limitations of data.

Feedback and Improvement: Establish two-way feedback channels. On one hand, promptly feed back evaluation results to responsible entities through performance briefing meetings, departmental special communication meetings, etc., clarifying strengths and weaknesses. On the other hand, set up suggestion collection channels to gather employee suggestions on HSE management. For issues identified in evaluations, establish a closed-loop improvement process of Problem List - Responsibility Assignment - Corrective Measures - Tracking Verification to ensure timely problem resolution.

-

Digital Tools Enabling Closed-Loop Management

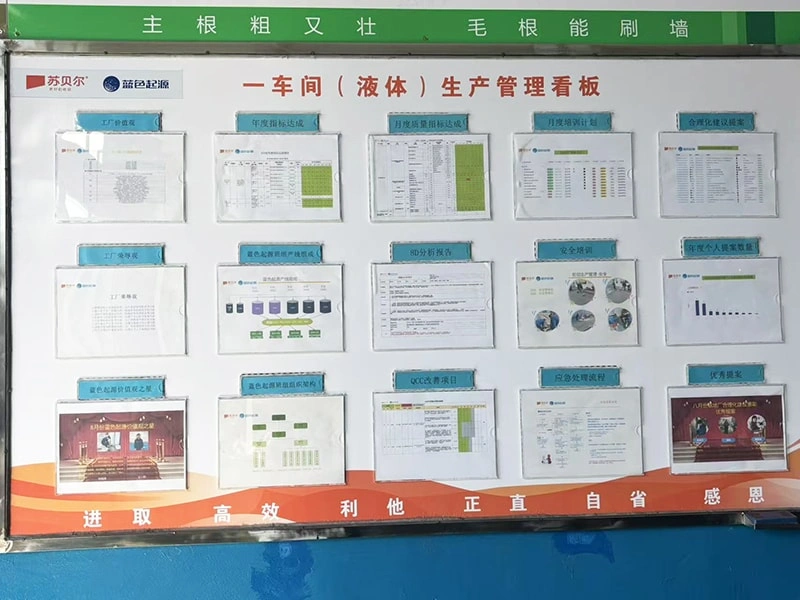

Leverage digital technology to enhance the efficiency and precision of HSE performance management, achieving visual control of the entire process:

Digital Realization of Closed-Loop Management: Build an integrated HSE management system that integrates functions such as indicator data collection, automatic analysis, and corrective task tracking. Establish full-process closed-loop nodes in the system, from indicator setting to improvement, with clear time nodes and responsibility permissions set for each node. For example, when the system detects that a safety hazard has not been rectified on time, it automatically sends a reminder notification to the responsible personnel and synchronizes it to the management dashboard, ensuring no corrective task is missed; after rectification is completed, the responsible personnel uploads verification materials, and only after review and approval can this issue node be closed, achieving full-process traceability.

Digital Support for Continuous Improvement: Use the historical performance data accumulated by the system for trend analysis and prediction, identifying weak links in HSE management, providing basis for optimizing indicator setting and adjusting management strategies. Simultaneously, build online training and knowledge sharing modules, pushing personalized safety training content based on employee performance, enhancing employee HSE awareness and skills, and assisting in the continuous improvement of performance levels.